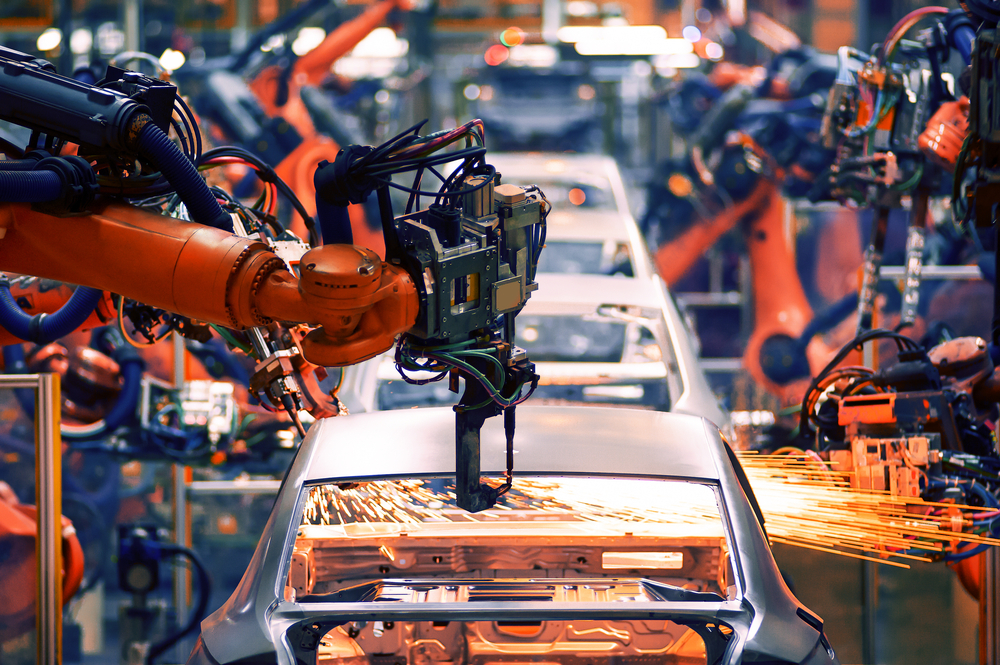

Big data analytics in manufacturing powering the industry

With the high rate of adoption of sensors and connected devices, there has been a massive increase in the data points generated in the manufacturing industry. These data points can be of various types. Data types range from a metric detailing the time taken for a material to pass through one process cycle to a more complex one, like calculating the material stress capability in the automotive industry.

With this surge in data available, there is no wonder why big data analytics in manufacturing is a hot topic.

Manufacturing remains a critically important part of the world’s economic engine, but the role it plays in advanced and developing economies has shifted dramatically. The manufacturing industry market was valued at $904.65 million in 2019 and is expected to reach $4.55 billion in 2025.

Big data is essential in achieving productivity, improving efficiency gains and uncovering new insights to drive innovation. With big data analytics in manufacturing, manufacturers can discover new information and identify patterns that enable them to improve processes, increase supply chain efficiency and identify variables that affect production.

Leaders in manufacturing enterprises understand the importance of process – KRC research study found that 67 per cent of manufacturing executives planned to invest in data analytics, even in the face of pressure, to reduce costs in this volatile climate.

To understand big data analytics in manufacturing and its impact, let us dive into how it’s intervention helps streamline operations.

Optimising asset performance and operations

Since manufacturing profits rely heavily on maximising the value of assets, asset performance gains can lead to big productivity improvements. By the same token, a reduction in asset breakdown can reduce inefficiencies and prevent losses. For these reasons, manufacturers focus on maintenance and continuously optimise asset performance.

Machine logs contain data on asset performance. This data is potentially of great value to manufacturers, but many are overwhelmed by the sheer volume of incoming information. Data analytics can help them capture, cleanse and analyse machine data to reveal insights that can help them improve performance.

In addition to enabling historical data analysis, data can drive predictive analytics, which manufacturers can use to schedule predictive maintenance. This allows manufacturers to prevent costly asset breakdown and avoid unexpected downtime. A study found that big data analytics can reduce breakdowns by up to 26 per cent and cut unscheduled downtime by nearly a quarter.

Improving production processes and supply chains

In an increasingly global and interconnected environment, manufacturing processes and supply chains are long and complex. Efforts to streamline processes and optimise supply chains must be supported by the ability to examine every process component and supply chain link in granular detail. Data analytics gives manufacturers this ability.

With the right analytics platform, manufacturers can zero in on every segment of the production process and examine supply chains in minute detail, accounting for individual activities and tasks. This ability to narrow the focus allows manufacturers to identify bottlenecks and reveal underperforming processes and components. Analytics also reveal dependencies, enabling manufacturers to enhance production processes and create alternative plans to address potential pitfalls.

Making product customisation feasible

Traditionally, manufacturing focused on production-at-scale and left product customisation to enterprises serving the niche market. In the past, it didn’t make sense to customise because of the time and effort involved to appeal to a smaller group of customers.

Data analytics is changing that by making it possible to accurately predict the demand for customised products. By detecting changes in customer behaviour, data analytics can give manufacturers more lead time, providing the opportunity to produce customised products almost as efficiently as goods produced at a greater scale. Innovative capabilities include tools that allow product engineers to gather, analyse and visualise customer feedback in near-real time.

According to a Deloitte review of the rise of mass personalisation, the ability to postpone production gives manufacturers new flexibility that allows them to take on made-to-order requests. The ability to postpone production can reduce inventory levels and improve plant efficiency. A streamlined manufacturing process is not only beneficial – it gives manufacturers a way to maintain efficiency while customising manufactured goods.

Big data analytics in manufacturing and the way forward

Big data analytics in manufacturing presents many promising and differentiating opportunities and challenges.

According to a McKinsey report, worldwide consumption will nearly double to $64 trillion. In such a scenario, data analytics provide manufacturers with a huge opportunity to predict, innovate and implement their approaches.

For more information on how big data analytics in manufacturing is powering the industry, visit our website!

Big data analytics has helped improve the productivity of many industries such as the manufacturing industry. Your organisation can also enjoy the benefits of leveraging your data analytics with the Selerity analytics desktop.